What are the precautions for metal stamping processing operations and their service life

When stamping parts are in operation, it is necessary to regularly check the punch turntable and the die mounting base of the stamping parts, so as to ensure the coaxial accuracy of the upper and lower turntables. Metal stamping parts should be strictly inspected before installation and use, dirt should be removed, and the guide sleeve and die of drawing stamping parts should be carefully checked for good lubrication.

In order to ensure the service life of the tension and compression parts, the spring of the mold should be replaced regularly to prevent the fatigue damage of the spring from affecting the use of the tension stamping parts. When installing the mold, the stamping personnel should use soft metal manufacturing operating tools to prevent damage to the stamping parts when knocking and crushing during the installation process.

When the punch and die cutting edges of stamping parts are worn, they should be stopped in time and sharpened in time, otherwise it will rapidly expand the wear of the mold cutting edges, accelerate the wear of the mold, and reduce the quality of the punching parts and the life of the mold. According to the installation procedure of the mold, install the male and female molds on the turntable to ensure that the direction of the convex and concave drawn stampings is consistent. In particular, the stampings with orientation requirements should be carefully installed to prevent incorrect installation and reverse installation.

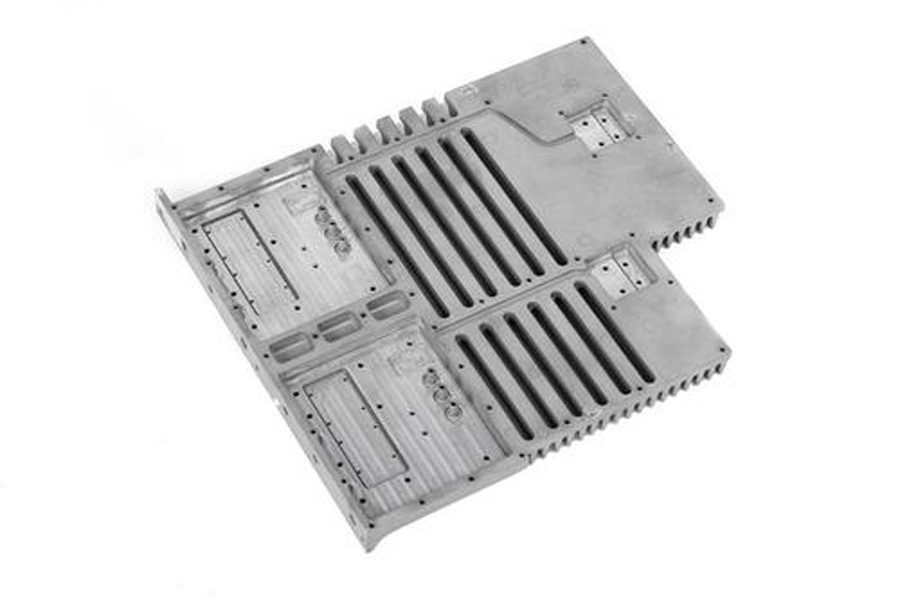

Six points that should be paid attention to in the production of stamping parts. Share the above content. The service life of stamping parts not only depends on reasonable mold structure, ultra-high manufacturing accuracy and good heat treatment effect, but also depends on the correct use, maintenance and maintenance of molds.

What are the precautions for metal stamping processing operations?

1. Check whether various equipment and materials are properly prepared.

2. Operators and mold repairers are strictly prohibited from reaching into the mold during production.

3. When installing the suction fan, the operator is strictly forbidden to reach out to the motor to clean up the waste.

4. It is strictly forbidden to wear slippers when going to work, so as not to hit your feet with molds and iron blocks in the workshop. Monitors, fitters, and mold repairers must wear protective shoes when going to work;

5. It is strictly forbidden for male operators to wear long hair, and for female operators, long hair should be coiled up to prevent long hair from getting caught in the flywheel.

6. Other oils such as white electric oil, alcohol, cleaning agent, etc. should be fireproof.

7. When packing materials, scraps and molds, please wear gloves to avoid scratching your hands.

8. When there is oil, it must be cleaned up in time to avoid slipping and falling.

9. It is strictly forbidden to wear gloves when drilling and milling machines; when using grinders, please wear masks and eye protections to protect yourself.

10. Pay attention to drag the mold to prevent it from falling on the ground (you must put the flatbed cart down to pull the mold).

11. It is strictly forbidden for non-electrical personnel to connect to electricity and repair the machine.

12. It is strictly forbidden to blow the wind gun at people, which can easily hurt the eyes.

13. The operator needs to wear earplugs.

14. When the machine is found to be abnormal, turn off the power first, and then ask the technician on duty to deal with it in time. It is not allowed to deal with it without authorization.